Okay so a little while ago I showed you some photos of a lithium battery I had purchased to replace the lead-acid a relatively heavy 12kg monster!

The issue I had was that the battery I had bought was not waterproofed. I got it for a fairly sensible amount from a German company I-Tecc.

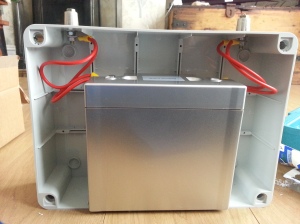

So I bought an enclosure for it an IP-55 electrical junction box – a little larger than the new battery but more similar in size to the old battery. I’d probably aim for a slightly smaller one if I made this again.

Lithium battery, enclosure and electrical terminals/bolts.

Lithium battery, enclosure and electrical terminals/bolts.

So it was just a case of making up some leads to connect the battery to the terminals which were to be placed on the outside of the enclosure. In order to ensure waterproofing the terminals and the bolts holding them in, have silicone sealer between them.

I have used two leads on each pole as the cables are rated at 27A each so they can handle 54A with two connected and it allows redundancy should any one lead come loose from its crimped on-terminal. I am presuming 54A will be sufficient for the auxiliary systems in the Leaf, but I would NOT consider this adequate for replacing a starter battery in a regular car (the starter can draw several hundred amps albeit only for a few seconds), the battery can handle it but heavy gauge wire and connectors would be needed. I might add fuses to the positive leads at some point, though all the connections to the postive side of this battery in the car are fused.

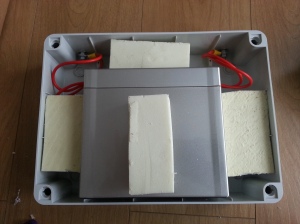

Then it was just a case of adding a little foam insulation so stop the battery rattling around and some labels to make it look all professional and such-like. I will add another label (reading “not to be used to start an internal combustion engine” later).

And here it is installed in the car. The hold down rod needed to be extended on the front of the battery as this enclosure is slightly too tall. The wiring to the positive connector was a little tight fitting but it is substantial and this should also ensure it is very unlikely to come undone. The positive terminal itself on the regular battery is slightly larger, presumably to discourage reverse polarity (big-badda-boom!). So I will for the sake of neatness and professionalism need to get a terminal sheath to widen the terminal, if you are thinking of doing this yourself, buy the terminals which are two different sizes in the first place! Whilst I was removing the old battery I connected a starter pack to the car’s leads to keep my settings from being erased from the car’s computer, although only a few trivial settings are stored in non-permanent memory.

I switched the car on and it seems to be working just fine. I might keep the starter pack in the boot for the first few journeys though, it might be very embarrassing to have to ask someone for a jump-start for my electric car!

Will it all be worthwhile? Well there are four things I hope to have achieved by doing this:

- Lighten the vehicle by 8kg. The now-waterproof Lithium battery assembly weighs 4.29kg, the original batttery weighs 12.0kg.

- Improve the car’s environmental credentials by removing the 18th century full-of-lead battery.

- Improve reliability as the lead-acid battery is a known weakness on the leaf (and every other vehicle into which one is fitted).

- Eliminate hydrogen gas, which can be given off when a lead-acid battery is charging and is the cause of the heavy corrosion often seen around battery trays (the reason they are now plastic, and why vehicles with batteries within the cabin have vent tubes to vent the hydrogen away from the car).

The only thing left to do is monitor the battery from the point of view of charging. Lithium batteries are not tolerant to overcharge and they are not suitable for float charging. I have not been able to find out the lead-acid battery management algorithm the Leaf uses, but a contributor to the US Leaf forum has been using one which cost him $800 for over a year and has not had any issues. The only information I have is that the car uses the lead acid battery as a starter battery to initialise its systems, connect the main traction-battery-pack and then it ceases to use the lead acid battery the auxiliary systems are run off the DC/DC converter. It then probably charges it in some way. If the car is left unused the car charges the lead-acid battery every five days using the traction battery.

In this sense it is a far more robust system than a regular ICE car which does nothing to prevent its lead acid battery discharging whilst in the airport car park for example, giving the AA an easy gig to attend when you return from your holidays. To monitor the new lithium battery I have ordered a battery monitor which plugs into the cigarette lighter (suppose we ought to be calling this the “accessory-port” now). It also has a thermometer for the cabin temperature, useful as few cars, the Leaf included, have an internal thermometer fitted so you can see how effective your climate control is, and a 2A USB phone charger built in.

This part if available here. No idea how well/if it works as I haven’t got it yet. I would have preferred a gadget more like this which is a very clever bluetooth battery monitor which reads out on your phone, and was designed for drones/quadrotors, so its very light.

One other thing – the lithium battery I am using has a built in battery management system (BMS) which is important unless you intend to remove the battery frequently and manually undertake maintenance like charging (with a proper Lithium battery charger) and cell-balancing. Lithium batteries are made up of a number of cells, in the case of a battery designed to replace a 12v unit, it is 4 cells (3.2-3.6v each) but which are invariably not all manufactured precisely to the same capacity. A balancer equalises the voltage across the cells so that no one cell takes too much of the load and heats up too much. The BMS handles this for you (and should provide some cut off facility to prevent over-charge or over-discharge). Cheaper Lithium batteries are available without this feature. More expensive batteries like the $800 battery mentioned earlier are available which have BMS and are waterproofed.

Total cost? £110 for the battery, £10 for the enclosure, £8 for the terminals, £10 misc bolts/screws. So lithium replacement battery £138, expected lifetime is 5 years minimum possibly 10 years. A typical lead acid battery subjected to British winters might last 3 years if you’re lucky albeit with some noticeable drop in performance and will cost £70.

As for the lightweight wheels my Supra mk3 alloys arrived after the usual delivery company shenanigans. Unfortunately despite being a generally easy guy to deal with the seller was not so good at using scales and they weigh 8.3 kg not the 6 kg he said they were. So I will resell them, it’s not worth the trouble to swap them out for a total saving of 10kg. Might have to be new shiny alloys which can come out of the insurance payout for the broken spoiler – of course there is no progress on this as yet.

Is the lithium battery still working ok in your leaf after 3 years?

LikeLike

Yes in fact I am just about to publish my 3 year update to this blog today. Details will be there.

LikeLike